Underground Drainage

Info

Info

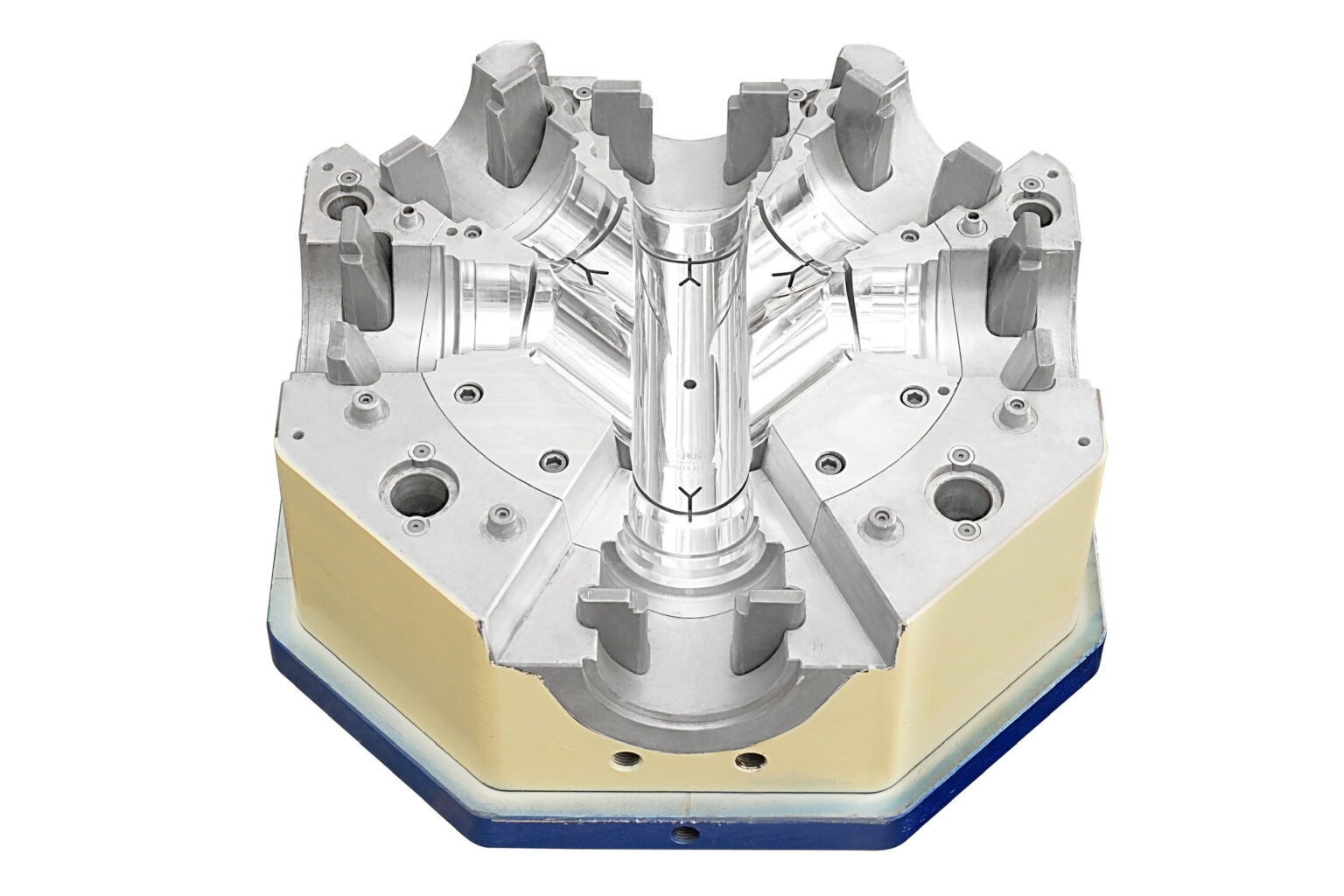

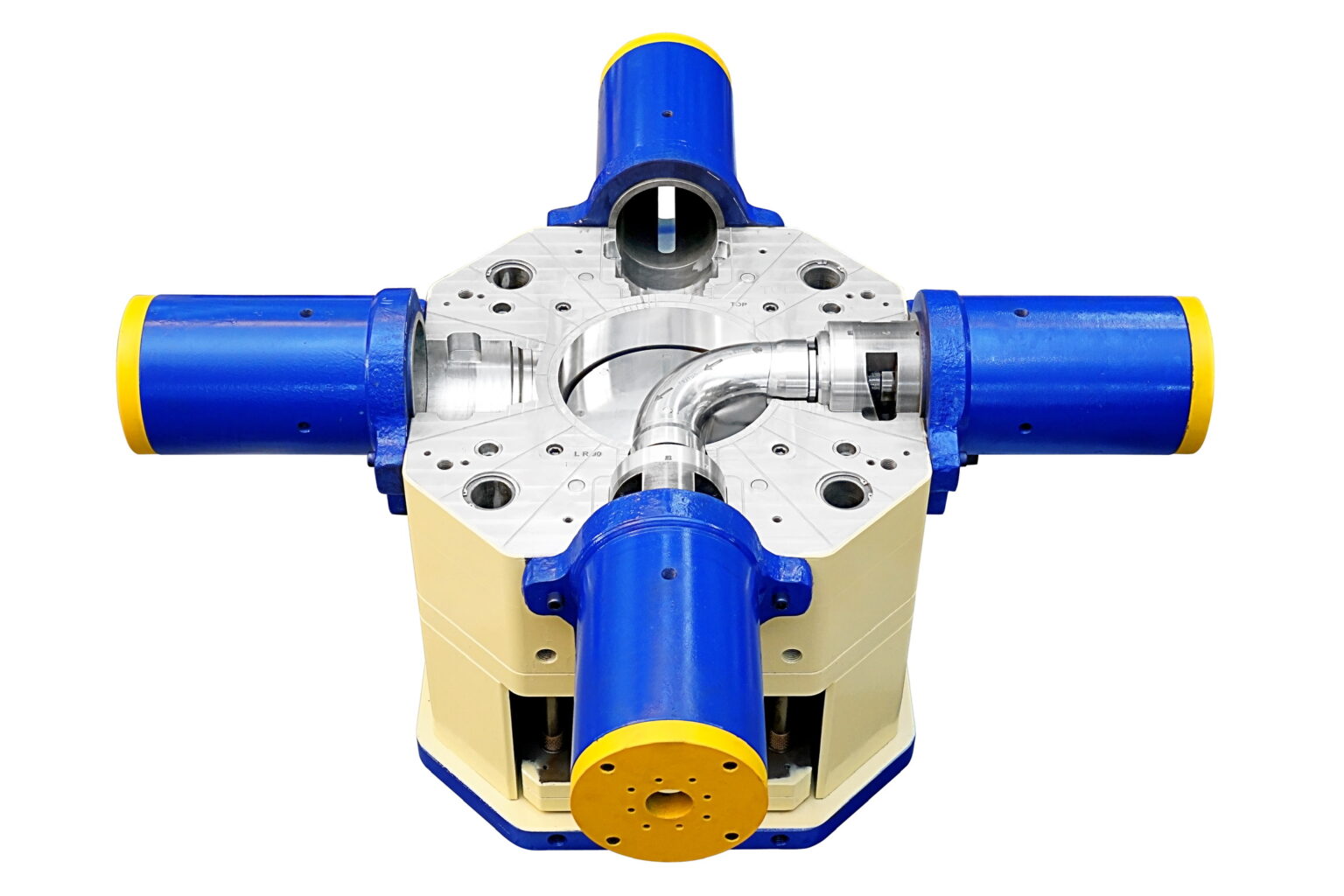

Inspection chambers are used when there are too many long sewage segments, at the converging inlets, change of direction, for new connections, to disconnect public and private sewer lines and at places of sewage fall.

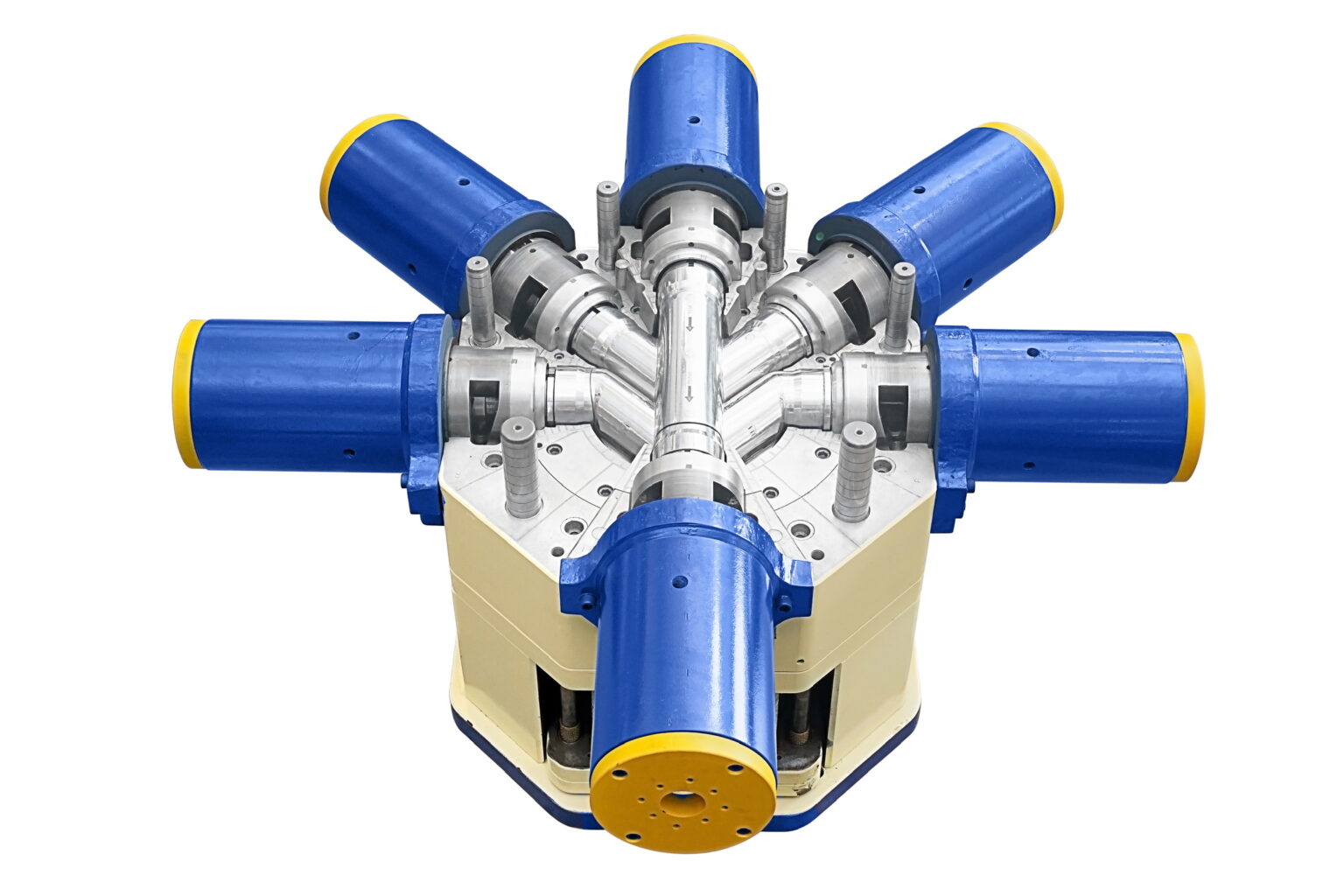

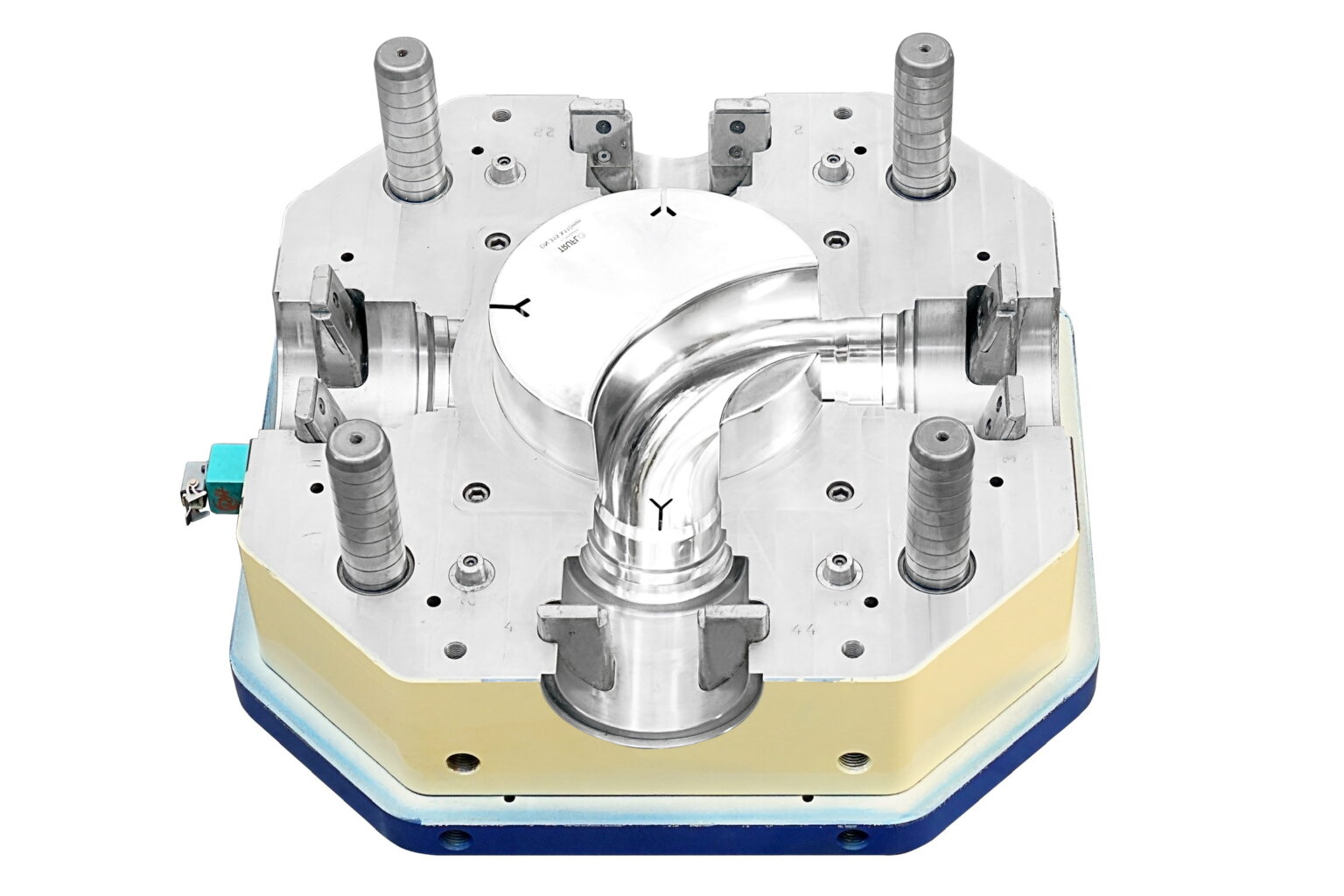

Sizes ranging from 315mm to 450mm with collapsible core