SWR Fittings

INFO

INFO

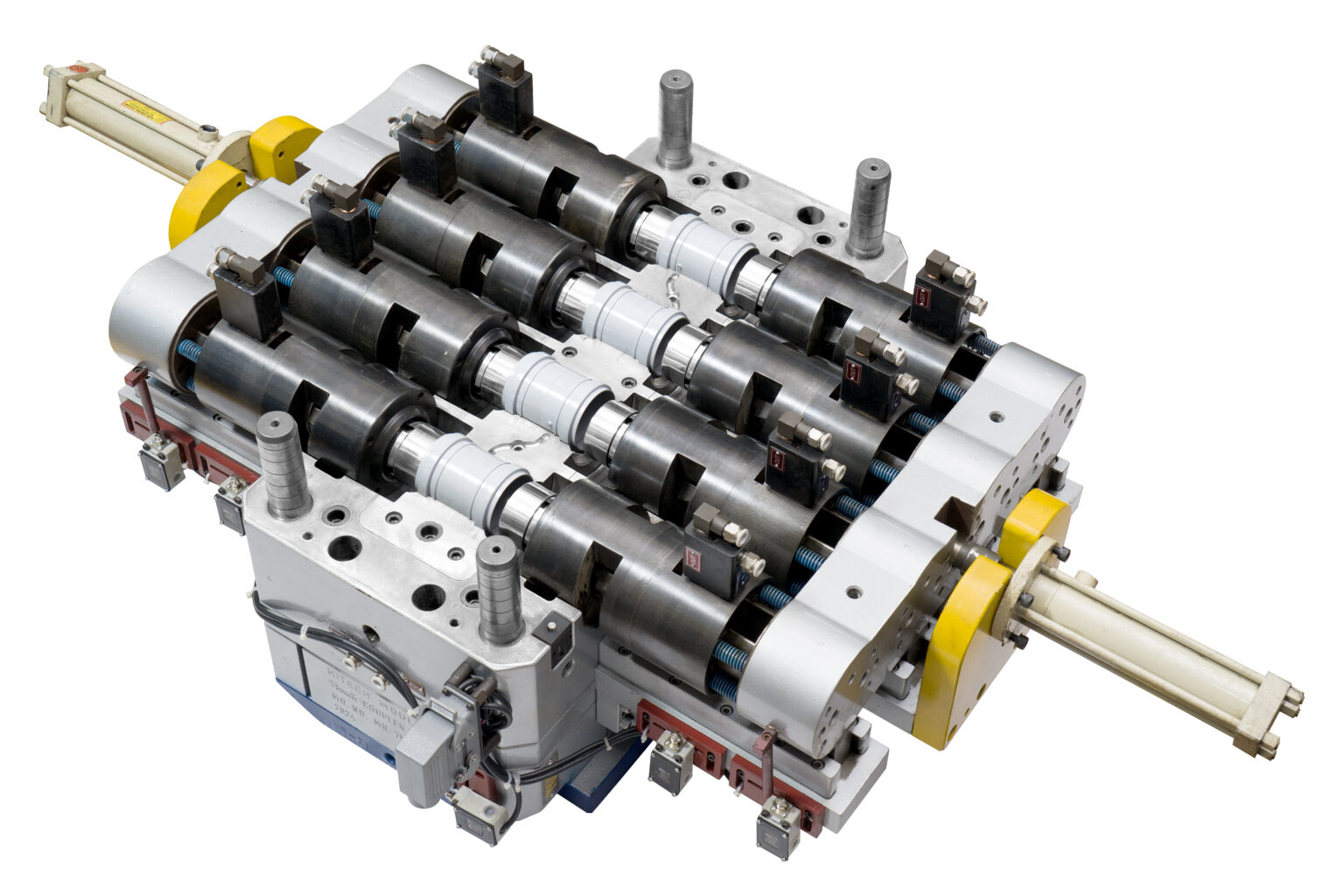

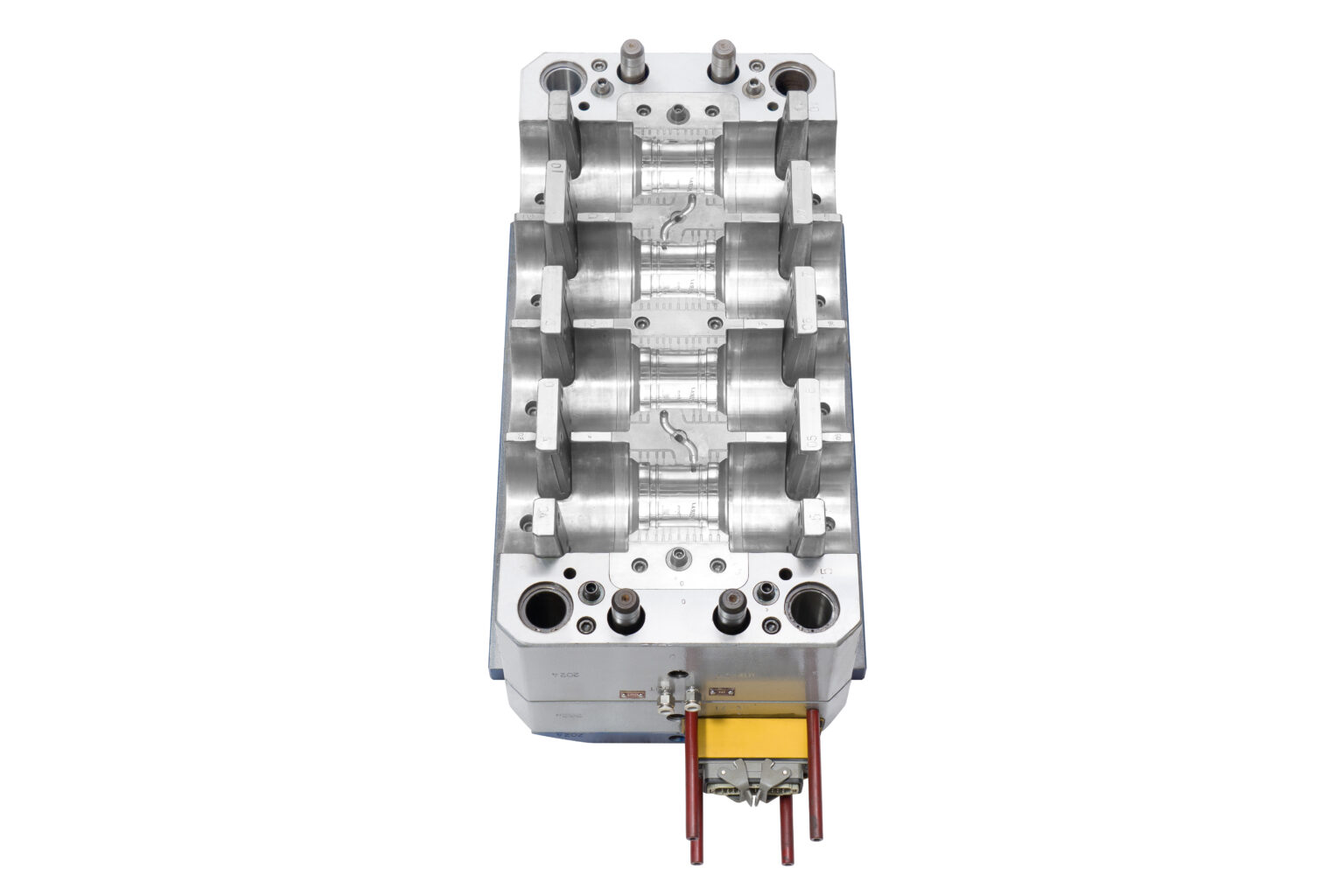

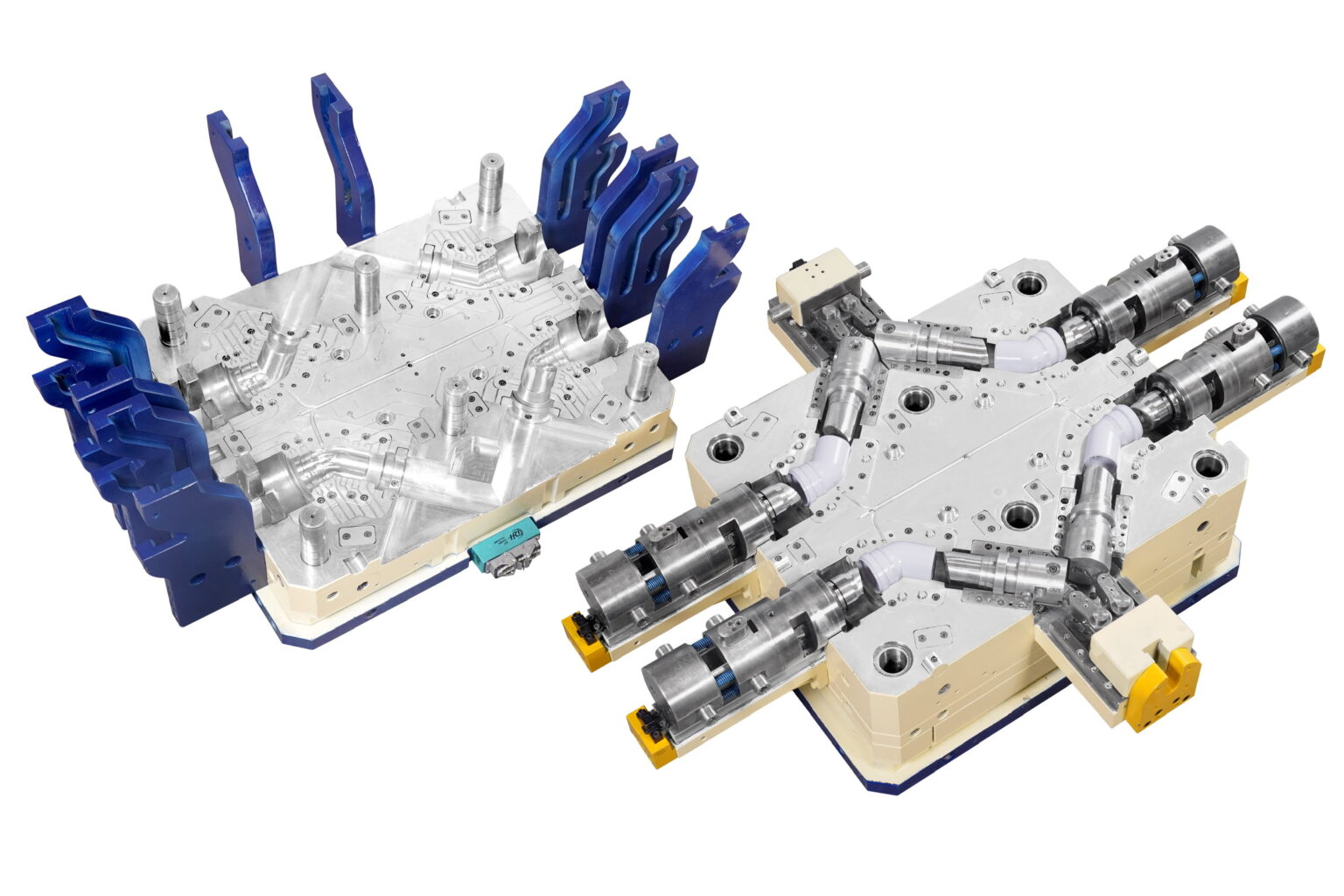

SWR pipes and fittings are used for non-pressure plumbing applications, such as transportation of soil, waste and rainwater, non-pressure industrial drainage applications, and waste discharge systems. Optimised cooling used both for the cores &cavities to reduce cycle time &increase productivity. Moulds are produced from high-grade German steel and with hardening 38-42 HRC. Beryllium Copper is applied in the punch to make the cooling more efficient.